Jinkun has been involved in the manufacturing and supply of gravure presses, laminators, and embossing machines for over a decade. These high-quality pieces of equipment are widely used for decoration, advertising, packaging, labeling, and other industrial applications.

Featuring compact structures, wide processing size, and high configuration flexibility, our machines are suitable for the processing of PVC, PE, OPP, BOPP, PET, non-woven cloth, paper and other flexible materials with outstanding results. The laminating-embossing combine machine can synchronize printing and embossing, resulting in film products with high precision, three-dimensional patterns.

Jinkun’s founder has been involved in the gravure press industry since 2000. On a professional journey starting as an apprentice and working his way to leadership positions, he had communicated with customers and accumulated significant manufacturing, sales, and service experience.

With thorough knowledge of machine structure and an understanding of customer requirements, he was able to form our company and help it grow.

He established a customer-first company culture built around the values of honesty, respect, passion, and performance.

With a comprehensive collection of processing equipment, we can independently produce all components needed in our machine with the exception of their motors, to optimize the performance of the equipment.

Utilizing high-quality components produced in-house, we can maintain better control over the cost and overall quality of our products.

Machines will be debugged and installation teams can be dispatched to better satisfy your needs and lifelong services will be provided.

Contact us at any time if you experience any problems with your machine. We sincerely thank every customer who has supported us and our products and look forward to the opportunity to work with you.

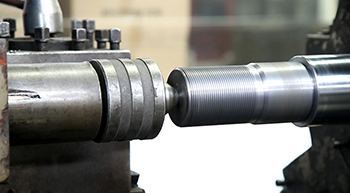

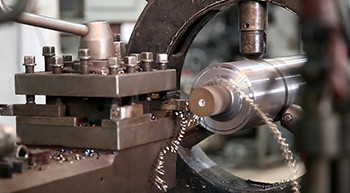

Independent components processing

Our factory is equipped with a complete set of equipment to produce components needed in our machines by ourselves.

Surface treatment and precision processing

We perform multiple processing procedures for all parts, including heat treatment, electroplating, etc. We will also carry out special precision processing for rollers, gears, transmission retainers, bearing seats, and other precision parts.

Manual welding

Machine welding is great for repetitive mass production; however, manual welding is applied in our factory as it leaves no welding defects, making it suitable for customized products.

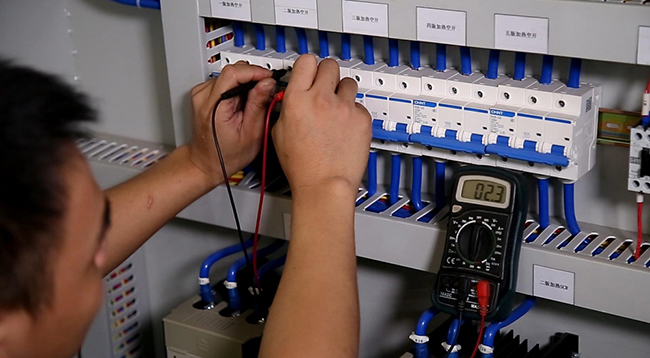

Testing

Prior to delivery, we will install and debug the machines in our factory until they run as expected.