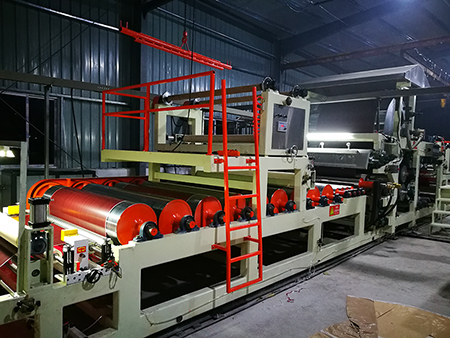

JK-LE 1600-Laminating-Embossing Combine Machine

- Cylinder width: 1600mm

- Material roll diameter: 600mm

- Laminating layers: 2

- Laminating speed: 0-60m/min

- Heating method: electrical heating

- Power consumption: 170KW

- Applicable materials: PVC

The machine features integrated laminating and embossing, achieving high working efficiency and reduced cost.

The laminating-embossing combination machine features a working width of 1600mm. In order to save space, the machine carries out laminating or embossing through a simple switch between different rollers.

Configuration information

- servo motor controller (Delixi)

- servo motor (Delixi)

- PLC system (Mitsubishi)

- pressure regulator (Fujikura)

- frequency conversion detector

- temperature meter

- electric cabinet

- rewinder

- unwinder

Customization

- Laminating-embossing machine with a heating lamination mode is ideal for laminating PVC and other flexible materials, such as wallpaper and tablecloths, as well as embossing corresponding patterns onto the material surface. Not only do we provide laminators with standard configurations, but we also offer customization options for special heating methods and sizes.

- Laminating width: 1-4.5m.

- Laminating layers: 2-6.

These processes are all carried out by the laminating-embossing machine:

Unwinding

A duplex unwinder design is used, with each station equipped with an independent motor. This allows material roll changing to be carried out without pausing machine operation and thereby improves work efficiency.

Preheating

Equipped with several heating rolls, the temperature in each machine part is uniform and independently manually adjustable between 50 ℃ to 200℃.

Each preheating roll’s bearing is automatically lubricated. Protective devices are added under suspended rolls to prevent falling.

Laminating/embossing

The oil temperature in the hydraulic cylinder keeps always stable using a cooling device on the cylinder, ensuring high precision in laminating or embossing.

Cooling

Several chill rolls are equipped to rapidly cool down the laminated/embossed material, maximizing the heat removal rate.

Trimming

The trimming width is adjustable according to the required laminating/embossing width.

- Rotogravure Printing Machine

- Laminating Machine

- PVC Film Printing Laminating Embossing Machine

- Embossing-Laminator

- Gravure and Emboss Combination Lines

- Slitter Rewinder

- Coating Machine

- Dongguan Jinkun Machinery Co., Ltd.

- Mobile: +86-13532886936

- E-mail: 1062046257@qq.com

- Tel.: +86-769-23611975

- Fax: +86-769-23611975

- WhatsApp:+86-13378473219

- WeChat:13378473219