Laminating Machine, Laminator

-

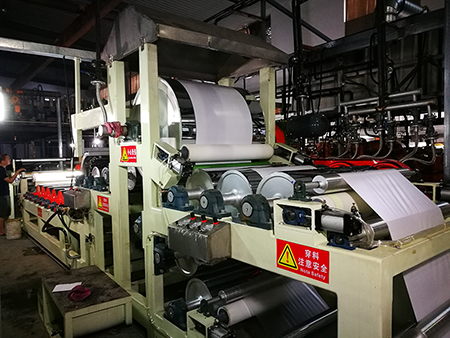

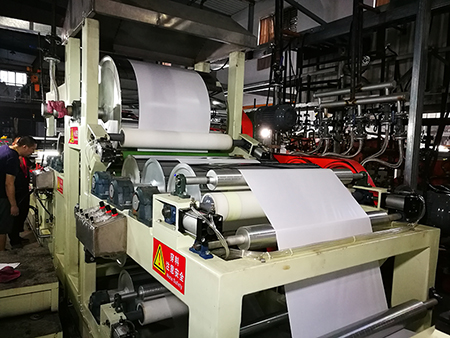

- JK-L1600-Laminating Machine, Laminator Max. film width: 1450mm Cylinder width: 1600mm Laminating layers number: 2-3

-

- JK-L2300-Laminating Machine, Laminator Max. film width: 2300mm Cylinder width: 2100mm Laminating layers number: 2-3

-

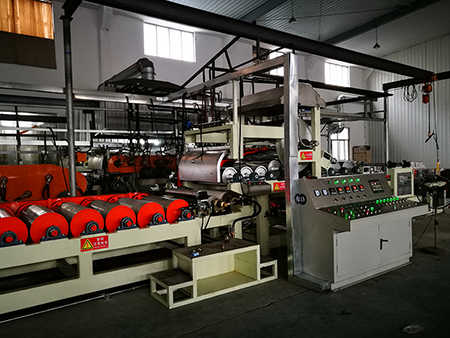

- JK-L2300-6 Laminator, Laminating Machine Web Width:2200mm Cylinder Diameter: 2300mm Laminated Layer: 2-8

Shown here are two standard laminators with a heating/adhesive laminating method. By changing the corresponding cylinder, both are easily turned into an embossing machine to print 3D patterns.

The customizable laminating width is 1 to 4.5m, with customizable laminating layers ranging from 2 to 6. All electrical configurations and heating methods are adjustable according to user requirements.

These processes are all carried out by the laminating-embossing combination machine:

Unwinder

A duplex unwinder design is used, ensuring each station is equipped with an independent motor. This allows material roll changing to be carried out without pausing machine operation and thereby improves work efficiency.

Preheating

Preheating is extremely important to laminators as each material layer needs to be heated to the right temperature to prevent deformation.

With a three-stage heating method and several heating rolls, the temperature remains uniform and is easily manually adjustable. Each pre-heating roll’s bearing is automatically lubricated, and protective devices are added under suspended rolls to prevent falling.

Laminating Machine

Both ends of the laminating cylinder are adjustable using a hydro-cylinder to ensure an even laminating performance.

Cooling

Several chill rolls are equipped to cool films and avoid deformation after the laminating process.

- We provide two laminator types according to different materials.

Lamination with heating: After heating, plastic films will shrink and attach to each other. - Lamination with adhesive: Before laminating, an adhesive will be applied to the plastic film (PVC, PVDF) and flexible materials (tablecloths, non-woven cloths and more). Materials are then waterproof and durable once the process is complete.

- Rotogravure Printing Machine

- Laminating Machine

- PVC Film Printing Laminating Embossing Machine

- Embossing-Laminator

- Gravure and Emboss Combination Lines

- Slitter Rewinder

- Coating Machine

- Dongguan Jinkun Machinery Co., Ltd.

- Mobile: +86-13532886936

- E-mail: 1062046257@qq.com

- Tel.: +86-769-23611975

- Fax: +86-769-23611975

- WhatsApp:+86-13378473219

- WeChat:13378473219