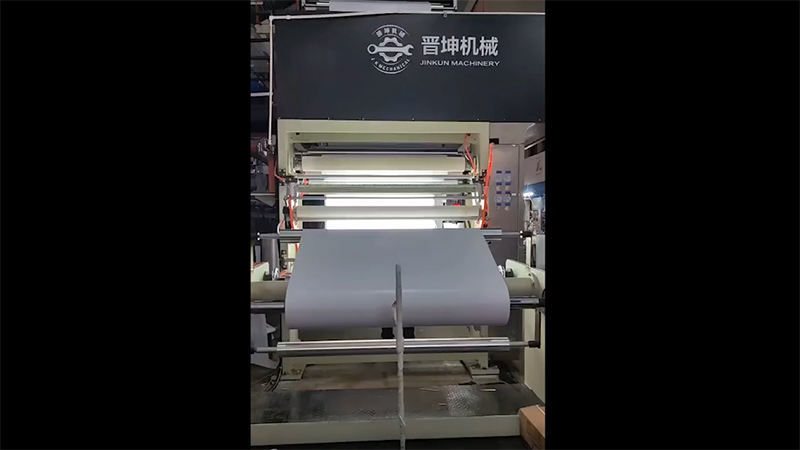

JK-1600 Gravure Press

PVC film printing, PET Film Printing, Bopp Film Printing

- Print width: 1500mm

- Print speed: 5-150m/min

- Color number: four

- Print precision: ±0.2mm

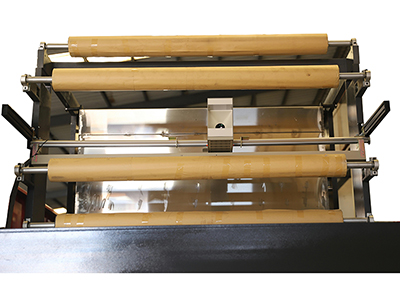

- Roller length: 1600m

- Roller diameter: 150mm-380mm

- Plate cylinder: shaftless

JK-1600 Gravure Press is specially designed for printing on flexible packaging films made of PVC, OPP, CPP, PET, Nylon, etc. The gravure printing machine features a maximum speed up to 150 m/min and tension range of 5-50 kg. The tension and speed vary depending on the different materials, which can be adjusted according to the different material properties to achieve excellent print quality.

- JK1600-5 Electronic Line Shaft Gravure Printing Machine

The advanced configuration of our gravure printing machines includes a motion control PLC system, servo control, a fully automatic color registration system and a still-image display for superior precision and efficiency. - JK1600-3 Mechanical Line Shaft Gravure Printing Machine

Our gravure printing presses are also available with mid-range configurations, which are equipped with a PLC system, variable frequency control, fully automatic color registration system and a still-image display. - JK1600-4 Mechanical Line Shaft Gravure Printing Machine

Gravure printing machines with basic configurations come with a PLC system and variable frequency control.

Application examples

Specifications

- Tension range: 5-50kg

- Tension precision: ±5kg

- Maximum pressing force: 1500kg

- Drying method: electrical heating (optional conduction oil heating)

- Weight: 35T

- Applicable ink: oily ink, water-based ink

- Applicable printing materials: flexible packaging films, such as PVC, OPP, CPP, PET, Nylon, PE and paper

Main configuration

- 1 shaftless duplex unwinder group

- 1 preheating unit

- 4 printing cylinder and drying system

- 1 tension control system

- 1 rewinding unit.

Customization

- Not only do we provide standard configuration gravure presses, but we also offer customization services to process materials with special widths and colors.

- Printing width : 1-4.2m.

- Print color: 1-12.

- All electrical configurations can be adjusted according to your requirements.

INQUIRY

Products

- Rotogravure Printing Machine

- Laminating Machine

- PVC Film Printing Laminating Embossing Machine

- Embossing-Laminator

- Gravure and Emboss Combination Lines

- Slitter Rewinder

- Coating Machine

Contact Us

- Dongguan Jinkun Machinery Co., Ltd.

- Mobile: +86-13532886936

- E-mail: 1062046257@qq.com

- Tel.: +86-769-23611975

- Fax: +86-769-23611975

- WhatsApp:+86-13378473219

- WeChat:13378473219