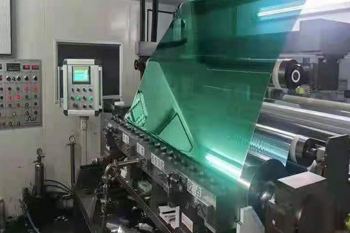

JK-1650 Coating Machine

- JK-1650 coating machine features high-precision coating technology, high productivity, high levels of energy efficiency, low maintenance and running costs.

Specifications

- Coated Substrate: release paper/film

- Coating Type: water based or oil based

- Max. Coating Speed: 120m/min

- Max. Mechanical Speed: 150m/min

- Guide Roll Diameter: 1650mm

- Max. Unwind Roll Diameter (substrate unwinding): ⌀ 1200mm

- Max. Unwind Roll Diameter (face material unwinding): ⌀ 1000mm

- Max. Rewind Roll Diameter: ⌀ 1000 mm

- Dryer - Design Temperature: 150°C; Operation Temperature: 100-130°C

- Dryer Length: 27m

- Motor Power: 129kW

- Heating method: thermal oil heating

- Web tension range: 0-20kg

- Machine Dimension (LxWxH): approx. 38500x4500x4700mm

Main Configurations

-

Substrate unwinding system

- Easy material loading

- Automatic tension detection, precise tension control Face material unwinding system

- Automatic tension detection, precise tension control

- Automatic roll change without machine stop eliminates downtime, greatly enhancing efficiency.

- Dryer: made using 304 stainless steel (interior)

- Rewinding unit: automatic roll change significantly reduces energy consumption and improves efficiency.

Features

- All parameters can be clearly displayed on the touchscreen in a real-time manner, and are allowed to easily set on the touchscreen.

- Automatic tension control system provides precise tension adjustment.

- The coating machine can be configured based on the coating methods, including micro-gravure coating, hard coating, solvent-free coating, UV coating.

- This coating equipment is compact and easy to use.

- Suitable for the production of optical film, insulation film, paint protection film, etc.

INQUIRY

Products

- Rotogravure Printing Machine

- Laminating Machine

- PVC Film Printing Laminating Embossing Machine

- Embossing-Laminator

- Gravure and Emboss Combination Lines

- Slitter Rewinder

- Coating Machine

Contact Us

- Dongguan Jinkun Machinery Co., Ltd.

- Mobile: +86-13532886936

- E-mail: 1062046257@qq.com

- Tel.: +86-769-23611975

- Fax: +86-769-23611975

- WhatsApp:+86-13378473219

- WeChat:13378473219